+49 (0) 5139 278641

Why Invest?

Why re-align / skim discs?

Skimming Brake discs should be carried out when:

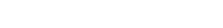

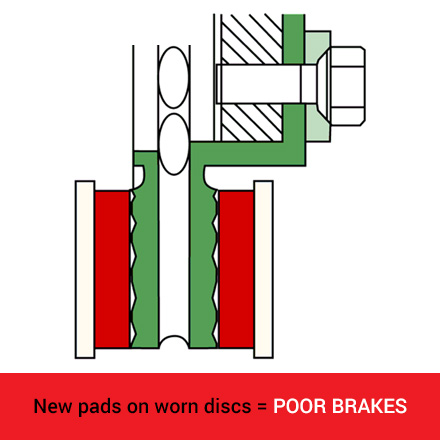

- Brake pads are changed but new discs are not necessary

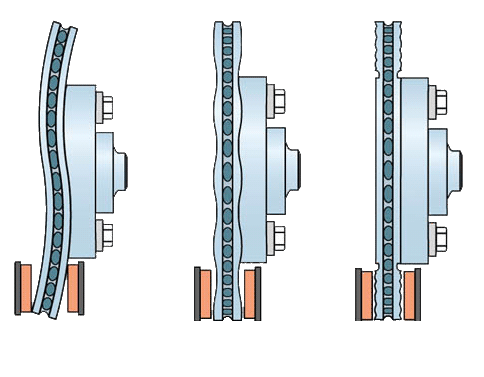

- There is brake vibration due to disc thickness variation (DTV) or run-out

- Discs are corroded

- Noise or Squeal needs to be eliminated

- To increase brake efficiency for the MOT test (Especially important on HGV’s and rear car discs)

How it works

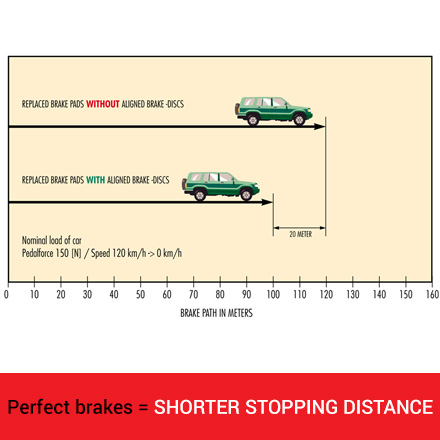

- The Dynastat lathe works on the vehicle, by attaching itself directly to the vehicle. Unique to our Disc Aligners is the system of parallel mounting which guarantees precise results. The mounting on the caliper ears ensures absolute parallelism between the pads and the discs. Other machines that use hub mounting can only try to get close to our exact results with strenuous external techniques.

- The technology eliminates run-out to an accuracy of always better than 0.02mm, normally around 0.01mm

The automatic surface machining (Skimming) of a disc is completed in around 4 to 5 minutes (car) and 10 minutes (truck). The complete process takes between 6 and 12 minutes per disc depending on the model. Normally less than 0.3mm of material is removed from the disc during the skimming process. The disc is not made thinner than its thinnest point, it’s just made flat!